blueprint trailer plans pdf

Blueprint Trailer Plans PDF offers detailed guides for building various trailers. With clear instructions and diagrams, it helps DIY enthusiasts create durable trailers like the 6’10” x 12″ utility model with a 3,500 lb capacity.

Understanding the Importance of Detailed Trailer Plans

Detailed trailer plans are essential for ensuring safety, durability, and functionality. They provide precise measurements, material lists, and step-by-step instructions, reducing errors and saving time. A well-designed blueprint, like the 6’10” x 12″ utility trailer plan with a 3,500 lb capacity, ensures your trailer is built to last. These plans also help DIY builders avoid costly mistakes and guarantee compliance with safety standards. With a matching parts kit available, the process becomes even more streamlined and efficient for users of all skill levels.

Why Choose PDF Format for Trailer Blueprints

PDF format offers unmatched convenience and clarity for trailer blueprints. It provides high-resolution, scalable diagrams and text, ensuring readability on any device. PDFs are easily shareable and accessible without special software, making them ideal for DIY projects. They also allow for zooming in on details, which is crucial for precise measurements. Additionally, PDFs are secure and can be stored conveniently, ensuring your trailer plans are always within reach. This format is perfect for detailed guides like the 6’10” x 12″ utility trailer plan, enhancing your building experience.

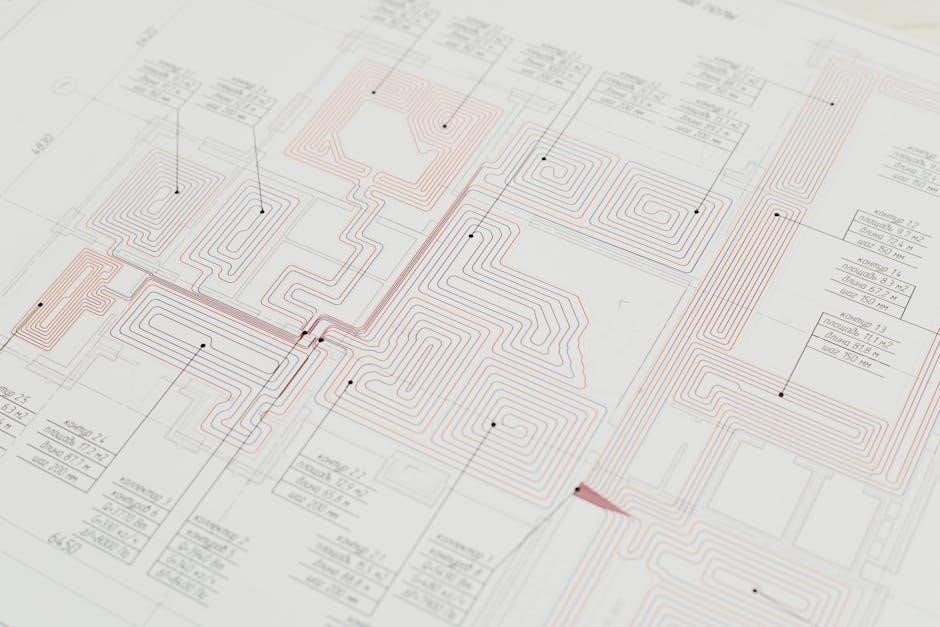

Key Features of a Comprehensive Trailer Blueprint

A comprehensive trailer blueprint includes detailed designs, precise measurements, and material lists. It features a 3,500 lb capacity utility trailer plan with matching parts kits. The blueprint provides step-by-step instructions, ensuring a smooth DIY experience. It includes axles, brakes, and wiring specifications, along with assembly guides. High-resolution diagrams and exploded views aid in understanding complex components. The plan also covers safety standards and customization options, making it ideal for both beginners and experienced builders. This ensures a sturdy, functional trailer tailored to your needs.

Types of Trailers Covered in Blueprint Plans

Blueprint plans include designs for utility, enclosed, and specialty trailers. Each type is tailored for specific needs, ensuring versatility and functionality in various applications and industries.

Utility Trailers: Design and Specifications

Utility trailers are designed for hauling heavy loads, featuring robust steel frames and durable materials. Plans include a 6’10” x 12″ model with a 3,500 lb capacity, ideal for transporting equipment or cargo. The design emphasizes functionality, with a focus on strength and versatility.Specifications like Model U82-144-35J highlight precise engineering, ensuring reliability. Customization options allow for tailored features such as storage compartments or tie-down points. Safety is prioritized through secure braking systems and proper lighting setups, making these trailers practical for various industrial and personal needs.

Enclosed Trailers: Layout and Construction Details

Enclosed trailers are designed for secure and weather-protected transport of goods. Their layout typically includes a sturdy steel frame, insulated walls, and a robust roof. Construction details emphasize durability, with materials like galvanized steel and aluminum often used. Features such as secure locking systems, ventilation options, and customizable interiors are common. Plans may include specifications for electrical systems, shelving, and tie-down points. The enclosed design ensures protection from the elements, making these trailers ideal for sensitive cargo or long-distance hauling needs.

Specialty Trailers: Custom Designs for Specific Needs

Specialty trailers are tailored to meet unique requirements, offering custom solutions for specific tasks. These designs cater to niche needs, such as motorcycle transport, horse trailers, or equipment hauling. Plans often include detailed layouts for interior customization, ensuring functionality matches the intended use. Materials like aluminum or galvanized steel are commonly specified for durability. Features such as adjustable shelving, tie-down points, or specialized flooring enhance versatility. Whether for recreational or industrial purposes, these blueprints provide the precision needed to build trailers that excel in their intended roles.

Materials and Tools Required for Trailer Construction

Building a trailer demands high-quality materials like steel beams, durable metals, and weather-resistant wood. Essential tools include welders, cutting saws, and precision measuring devices for accuracy.

Steel Frame: The Backbone of a Durable Trailer

A sturdy steel frame is essential for trailer durability and structural integrity. High-strength steel alloys are recommended for their resistance to stress and corrosion. The frame’s design must account for weight distribution and load capacity, ensuring stability during transit. Properly constructed steel frames minimize sway and enhance safety. Galvanizing or applying rust-resistant coatings can extend the frame’s lifespan. A well-engineered steel frame forms the foundation for a reliable and long-lasting trailer, making it a critical component in the construction process.

Essential Tools for Cutting, Welding, and Assembly

Building a trailer requires specialized tools for precise cutting, welding, and assembly. A high-quality angle grinder or circular saw is necessary for cutting steel frames accurately. For welding, a MIG welder is ideal, along with welding gloves, a helmet, and wire. Assembly tools include wrenches, sockets, and a torque wrench for securing bolts. Measuring tools like a tape measure and square ensure accuracy. Optional tools, such as a plasma cutter for intricate cuts or a drill press for holes, can enhance efficiency. Proper tools are crucial for a professional-grade trailer build.

Recommended Materials for Trailer Flooring and Sides

Durable materials are essential for trailer flooring and sides to ensure longevity and strength. Pressure-treated plywood or corrugated metal are excellent choices for flooring, offering resistance to moisture and heavy loads. For sides, aluminum panels or steel sheets are popular due to their lightweight and rust-resistant properties. Additionally, waterproof sealants and protective coatings can enhance durability. Choosing the right materials ensures your trailer withstands harsh conditions and remains structurally sound for years, making it suitable for various applications and payloads.

Step-by-Step Trailer Building Process

A well-structured process involves planning, cutting, welding, and assembling components. Follow detailed blueprints to ensure accuracy and safety, starting with the frame and progressing to the final assembly.

Preparation: Measuring and Cutting Steel Frames

Accurate measuring and cutting of steel frames are critical for a sturdy trailer. Use a tape measure and square to ensure precise cuts. Employ a saw or cutting torch for clean edges. Double-check measurements against the blueprint to avoid errors. Sand rough edges for safety and proper fitting. Organize all components before proceeding to assembly. Proper preparation ensures a smooth building process and a durable final product.

Welding Techniques for a Strong and Secure Frame

Proper welding techniques are essential for a durable trailer frame. Use MIG or ARC welding for strong, clean joints. Ensure the steel is clean and free of contaminants before welding. Apply consistent pressure and maintain proper angles to avoid weak spots. Clamp the frame securely to maintain alignment during welding. Inspect welds for strength and smoothness, reinforcing any gaps. Follow the blueprint’s welding patterns to ensure structural integrity. Quality welds are critical for safety and longevity, especially under heavy loads and stress.

Assembly: Putting It All Together

After preparing and welding the frame, the next step is assembly. Start by aligning the frame components according to the blueprint. Securely attach the tongue and axle, ensuring proper alignment for safe towing. Install the flooring and walls using durable materials like steel or aluminum. Add the roof and doors, sealing gaps for weather resistance. Finally, connect wiring, brakes, and lighting systems. Double-check all connections for safety and functionality. Proper assembly ensures a sturdy, reliable trailer that meets safety standards and performs well under various conditions.

Design Considerations for Optimal Trailer Performance

Designing trailers for optimal performance involves balancing weight distribution, improving aerodynamics, and incorporating customization options to enhance functionality, ensure long-term durability, and improve safety.

Weight Distribution and Load Capacity

Weight distribution and load capacity are critical for trailer stability and safety. Proper distribution ensures even load transfer across axles, preventing sway and uneven wear. Load capacity determines the maximum weight a trailer can safely carry. Exceeding this can lead to structural failure. Blueprint plans provide detailed specs to ensure builders adhere to these limits, using appropriate axle placements and materials. Adhering to these guidelines is essential for optimal trailer functionality, longevity, and compliance with safety regulations to avoid potential hazards effectively.

Aerodynamics and Stability on the Road

Aerodynamics and stability are vital for smooth towing and fuel efficiency. A well-designed trailer minimizes air resistance, reducing drag and improving handling. Rounded edges, streamlined shapes, and proper alignment with the towing vehicle enhance airflow. Stability is achieved through balanced weight distribution and lower center of gravity. Trailer plans often include specifications for optimal height and width ratios to prevent swaying. These designs ensure safer towing experiences and better control, especially at higher speeds or in windy conditions, making long trips more manageable and efficient.

Customization Options for Enhanced Functionality

Blueprint trailer plans offer extensive customization options to maximize functionality. Users can modify layouts, add compartments, and incorporate shelving to suit specific needs. Whether for utility, enclosed, or specialty trailers, these designs allow for tailored solutions. Additional features like tie-down points, adjustable dividers, and reinforced structures enhance versatility. Customization ensures the trailer meets individual preferences, improving efficiency and practicality for various applications, from personal use to commercial or recreational purposes.

Safety and Compliance in Trailer Design

Blueprint trailer plans ensure compliance with safety regulations, enhancing durability and reliability. They include features that meet legal requirements, ensuring secure and reliable trailer operation.

Meeting Local and International Safety Standards

Blueprint trailer plans PDF ensure compliance with local and international safety regulations, guaranteeing durability and reliability. They include detailed specifications for braking systems, weight distribution, and material quality, ensuring trailers meet legal standards worldwide. Adherence to these guidelines minimizes risks, enhances safety, and ensures legal operation across borders. By following these plans, builders can confidently construct trailers that pass inspections and meet stringent safety requirements, reducing potential liabilities and ensuring long-term performance.

Braking Systems and Lighting Requirements

Blueprint trailer plans PDF detail essential braking systems and lighting requirements for safety and compliance. Electric drum brakes and hydraulic systems are commonly specified, ensuring reliable stopping power. Lighting includes marker lights, brake lights, and turn signals, meeting visibility and regulatory standards. Proper wiring diagrams are provided to ensure correct installation. These features enhance safety, improve visibility, and comply with legal requirements, reducing the risk of accidents and ensuring trouble-free operation on the road.

Regular Maintenance Tips for Longevity

Regular maintenance ensures your trailer remains durable and functional over time. Blueprint trailer plans PDF emphasize inspecting the frame for rust, checking tire pressure, and lubricating moving parts. Cleaning electrical connections and securing bolts are also crucial. Schedule annual inspections of brakes and axles. Addressing minor issues promptly prevents costly repairs. Following these tips extends the trailer’s lifespan, ensuring safe and reliable performance for years to come. Proper upkeep also maintains your investment and avoids potential safety hazards.

Cost Considerations and Budgeting

Blueprint trailer plans PDF help estimate costs for materials, tools, and labor. Comparing DIY and pre-made options aids budgeting. Plan wisely to save without compromising quality.

Estimating Material and Tool Costs

Accurate cost estimation is crucial for trailer construction. Blueprint trailer plans PDF provide detailed lists of required materials and tools, ensuring budget accuracy. Steel, wood, and hardware costs vary based on quality and quantity. Tools like welders, saws, and drills add to expenses. Budgeting tips include buying materials in bulk and utilizing coupons. Plan meticulously to avoid overspending and ensure all components are accounted for before starting the project. This step guarantees financial preparedness and project feasibility.

Comparing DIY vs. Pre-Made Trailer Options

DIY trailer construction using blueprint trailer plans PDF offers cost savings and customization but requires time and expertise. Pre-made trailers provide convenience and warranty benefits but are more expensive and less customizable. DIY suits those with tools and skills, while pre-made is ideal for quick solutions. Weighing factors like budget, time, and personal expertise helps decide the best option. Both choices have pros and cons, so aligning them with specific needs ensures satisfaction and value.

Ways to Save Money Without Compromising Quality

Save money by buying materials in bulk and utilizing recycled or second-hand components when possible. Shopping during sales or using coupons can reduce costs. Simplify the design to avoid unnecessary expenses while maintaining functionality. Consider repurposing materials from other projects to minimize waste. Adhere to the blueprint trailer plans PDF to ensure accurate measurements and reduce material waste. These strategies help achieve a high-quality trailer without exceeding your budget.

Advanced Trailer Building Techniques

Explore expert strategies for enhancing efficiency and precision in trailer construction, utilizing modern tools and innovative methods to ensure durability and safety.

Using CAD Software for Custom Designs

CAD software revolutionizes trailer design by enabling precise, customizable blueprints. It allows users to create detailed 3D models, ensuring accurate measurements and optimal layouts for various trailer types.

With CAD, designers can experiment with different configurations, materials, and features, streamlining the planning process. This technology is essential for creating professional-grade PDF trailer plans tailored to specific needs.

Implementing Modern Materials and Technologies

Modern materials like aluminum alloys, high-strength steel, and durable polymers enhance trailer longevity and performance. These lightweight yet robust options improve fuel efficiency and reduce wear and tear. Advanced technologies, such as smart trailer sensors, enable real-time monitoring of tire pressure, temperature, and cargo status, ensuring safer and more efficient hauls.

Integrating automation tools and eco-friendly components into trailer designs aligns with current trends, making blueprints more versatile and sustainable. These innovations are seamlessly incorporated into PDF plans, offering builders cutting-edge solutions for modern trailer construction.

Tips for Building a Trailer That Lasts

To ensure durability, prioritize precise welding and secure frame connections. Regular inspections of bolts and hinges are crucial for maintaining structural integrity over time. Protecting the trailer from rust by applying durable coatings is another key step for longevity.

Using high-quality hardware and weather-resistant materials helps withstand harsh conditions. Proper alignment and balancing during assembly further enhance stability and reduce wear. Following these practices ensures your trailer remains reliable for years of heavy use.

The blueprint trailer plans PDF is an essential resource for any builder, offering clear guidance and cost-effective solutions. Start your project with confidence today for creating a durable trailer!

Final Thoughts on Building Your Own Trailer

Building your own trailer can be a rewarding experience, especially with a detailed blueprint trailer plans PDF. These plans provide clarity, saving time and reducing errors. They are cost-effective and customizable, catering to various needs. Whether you’re a DIY enthusiast or a professional, having a well-structured guide ensures a successful project. With the right tools and materials, you can create a durable, functional trailer. Embrace the process, stay organized, and enjoy the satisfaction of crafting something tailored to your requirements. Your journey to trailer ownership starts here!

Resources for Further Learning and Support

For further guidance, explore online forums, tutorials, and communities dedicated to trailer building. YouTube channels and DIY websites offer practical tips and visual guides. Check out eBooks and manuals from experts in the field. Manufacturer websites often provide detailed specifications and advice. Join local DIY groups or workshops to network with experienced builders. These resources will help you refine your skills and troubleshoot challenges. Stay updated with the latest trends and safety standards to ensure your trailer meets all requirements and performs optimally over time.

Encouragement to Start Your Trailer Building Journey

Embarking on your trailer-building journey can feel daunting, but with detailed PDF blueprints, you’re well-equipped to succeed. Remember, every project starts with a single step. Don’t be intimidated by the process—break it into manageable tasks. Celebrate small victories, and trust the plan. Building your own trailer is a rewarding experience that combines creativity and practicality. Take pride in crafting something tailored to your needs. Gather your tools, stay focused, and enjoy the satisfaction of creating something with your own hands. Start today and transform your vision into reality!